InfiniPleat®

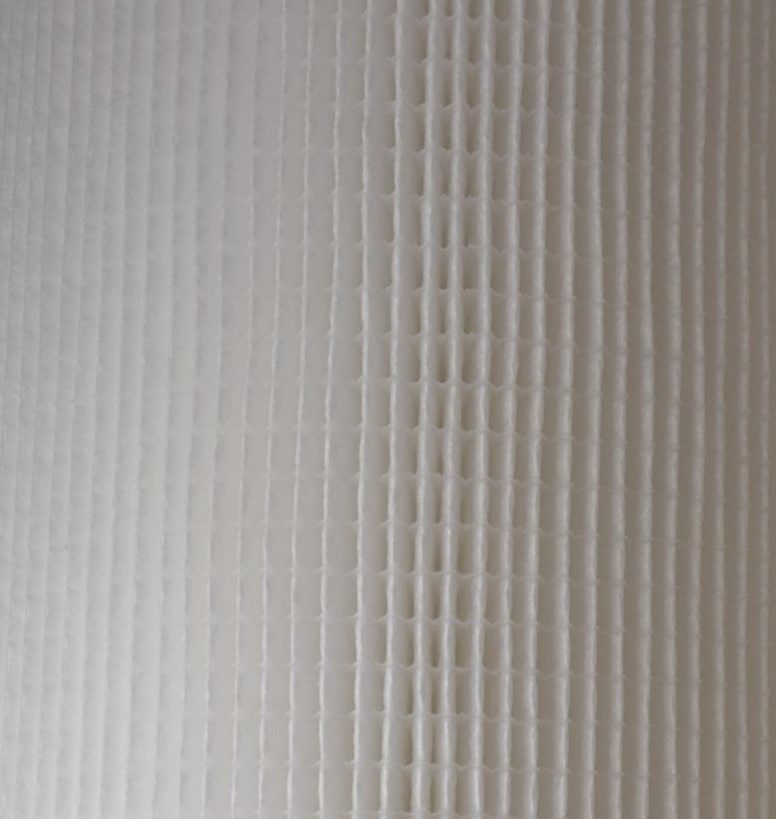

IREMA synthetic filter media is manufactured with a proprietary process which creates a unique media design for best in class energy efficiency. The integration of very fine fibers into a three-dimensional and progressive fiber structure provides the desired filtration efficiency at the lowest pressure drops with a maximum dust holding capacity. It is used in a large variety of HVAC, health and safety applications.

InfiniPleat®

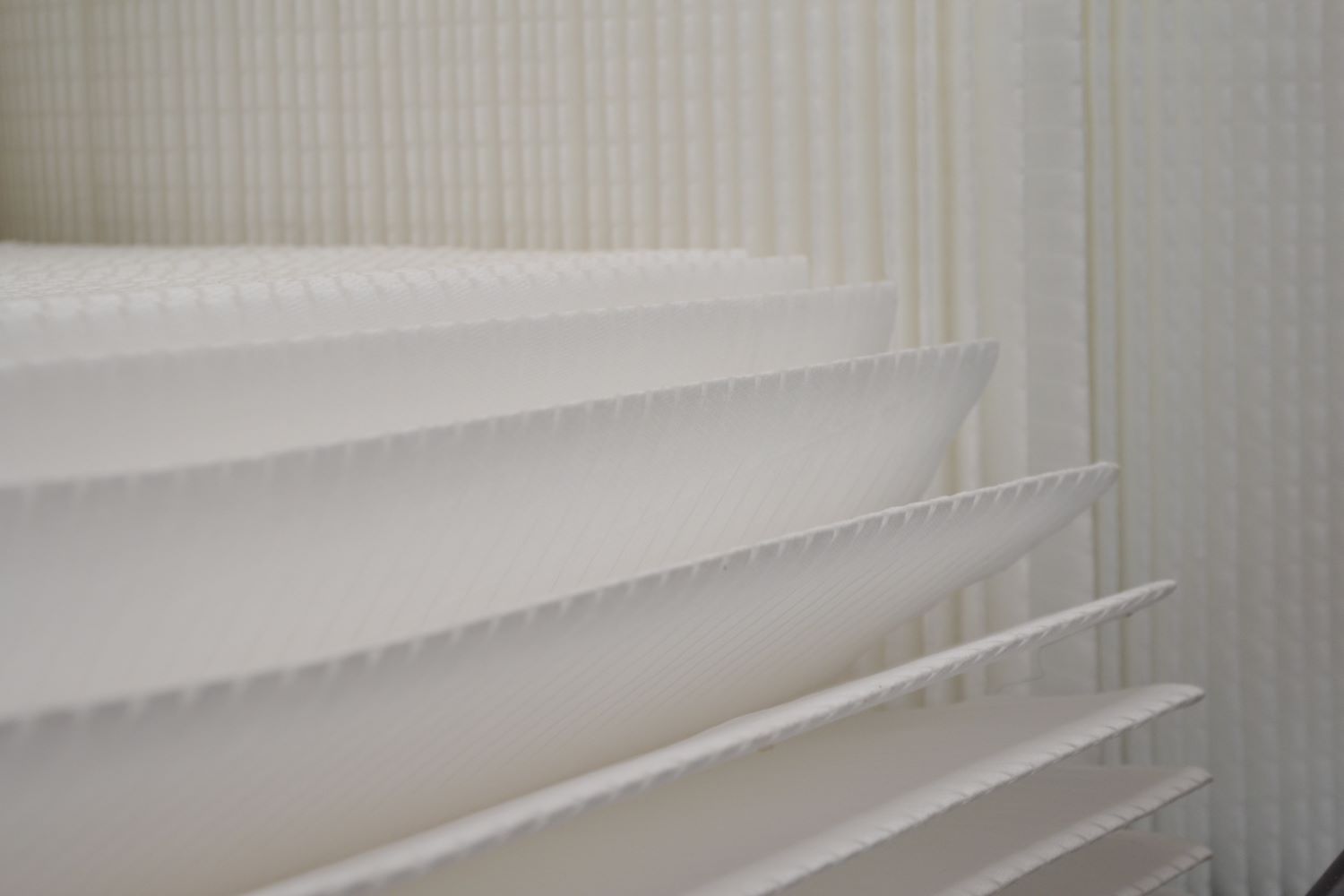

InfiniPleat® filters are manufactured as a continuous filter and are available in multiple lengths (12”-120”, depending on filter depth), depths and widths. On average InfiniPleat® filters offer 3-4 times more surface area. Because of its inherent design structure, InfiniPleat® does not require an external support frame. This creates a larger surface area that allows for a lower initial pressure drop and therefore reduced energy cost. For data center applications, this will mean a lower PUE ratio. InfiniPleat® is available in MERV 11 and 13 ratings. Another exciting feature with InfiniPleat® filters is that it can virtually eliminate all airflow bypass. This is accomplished by adjusting the filter height and length to match each track or pocket in the filter wall. When bypass is eliminated, you will have no more false differential pressure data readings.

InfiniPleat® filters are truly remarkable when it comes to depth loading and dust holding capacity. Our customers normally see 2-3 times longer filter life vs. conventional pleated filters.

If you want a filter that increases life span, holds more dust, lowers energy, and eliminates bypass; contact us to set up a trial run.

InfiniPleat® is engineered and manufactured with a proprietary web design that captures more particulate (maximum DHC) than other filters of the same size and MERV ratings.

WHAT SETS InfiniPleat® APART?

The difference is clear

InfiniPleat® is a custom sized, installed product that maintains the highest efficiencies (MERV 13-16) at the lowest pressure drops. It is engineered to eliminate bypass without compromising performance. Built to perform over an extended lifespan. InfiniPleat® filters are available in size depths of 5/8”, 1”, 2” and 4”. InfiniPleat® filters typically have a filter lifespan of 1-2 years depending on environmental conditions and airflow requirements.

- 4X the surface area of traditional pleated filters for maximum filtration and lowest fan energy cost

- Lower energy cost lowers your PUE ratio

- 2X the service life

- InfiniPleat® is 100% hydrophobic, antimicrobial, polypropylene nanofiber

- UL 900 listed

- Unique spacer beads provide unmatched media strength and rigidity for more surface area

- Due to the inherent media strength and rigidity, along with polypropylene spacers makes InfiniPleat® 100% recyclable

- Superior strength and rigidity to withstand wind, rain, snow and humidity

- Protects downstream equipment and people from harmful environmental elements

- Extends the life of downstream equipment

- InfiniPleat® is a registered trademarked product with the U.S.P.T.O.

WHY DO I NEED PROTECTION FROM BYPASS?

Think air filtration is simple?

It’s not. Standard filters have raw edges that allow moisture to be absorbed and degrade, causing them to lose shape and allow outside particles through. This is known as unwanted bypass. Thus, negating the reason for the filter. Once bypass occurs, toxins and other environmental particles freely flow into the facility. Our products and custom solutions fit your exact air filtration needs and eliminate bypass to keep you safe. We are so confident that you will love our products and services.

- InfiniPleat is designed to eliminate bypass by withstanding environmental elements without compromising performance

- InfiniPleat properly pressurizes to completely seal and eliminate bypass

- InfiniPleat completes a microbial moisture barrier

- InfiniPleat is custom sized and manufactured to prevent unwanted bypass

Did you know?

- A single 1mm gap will allow moisture and particulate to enter and affect filter efficiency by 2-5%

- A 10mm gap causes filters to be 10-30% less effective

- Microscopic dust particles are conduits for moisture

- Continual operation in humid environments can cause units to run hot

- Moisture and particulate can cause circuits to burn